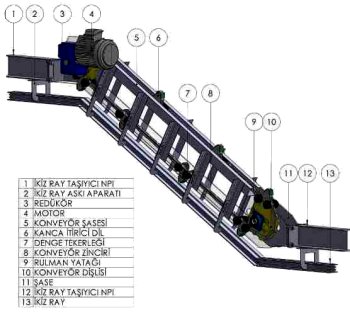

FUNCTION

After the slaughtering process is completed on a stand, sheep are transferred to

the lifting elevator with their back feet hanged on the bleeding hook. Sheep

slaughtered at a level lower than the bleeding line are taken by the lifting

elevator to the bleeding line with a suitable inclination. Sheep lifting

elevator may operate with the same chain with the position of the bleeding line

as well as in two separate systems. When the bleeding hook is mounted as fixed

on the lifting elevator chain, it rotates constantly together with the bleeding

line. In the transfer part, the released bleeding hook returns back to the

slaughtering area.

TECHNICAL CHARACTERISTICS

At conveyors made of special prepared bearing chains, the hook has pushing tips

with 1000 mm intervals. Those driving tips elevate the cut sheep with an

inclination of 30-45 degrees transferring them to the bleeding monorail.

Lifting elevator is operated at 2.2 kw driven with a worm screw engine reducer.

With the stretch gear mounted under the chassis, engine is started with the gear

activated by engine reducer. The bearing of gears to chassis is with rollers and

the mobile parts of those rollers are produced of polyamide.

When this elevator is manufactured of steel, full trunk of this elevator is

plated with hot submerged galvanize or made of full stainless material.