FUNCTION

Sheep with the slaughtering process completed, are transferred to the bleeding

line by the elevator. Along the lifting elevator, the bleeding process and

unwilling moves are partly reduced. Later when the bleeding line is reached,

both functions are considered as completed. This mechanism the length of which

is shaped according to the daily slaughtering capacity may be rectangular or in

a line along the slaughterhouse varying according to the physical state of the

slaughterhouse.

Sheep bodies rotating constantly are taken to the process line manually or with

an delivery apparatus at the last part of the line. On the bleeding line, first

the front arms and then partially the hide collars are opened as preparation for

the process line.

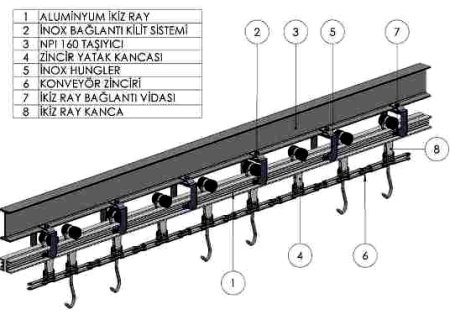

TECHNICAL CHARACTERISTICS

Bleeding line consists of galvanized pipe of 60x3mm and steel blade hangers at

the size of 16 x 50 mm connecting this pipe to carrier system.

Bleeding monorail is mounted with hangers under girders with a distance of 190

mm under the carrier NPIĺs.

Motor reducer system causes the chain and pallets to rotate constantly moving

the bodies from lifting elevators to slaughtering line and takes it to foot

changing apparatus.