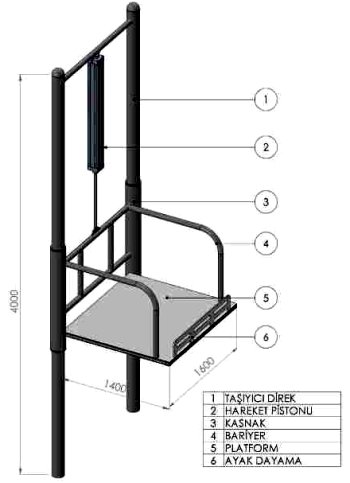

FUNCTION

The carcasses flayed with the internal organs taken out on the cutting band are

divided into 2 equal parts along the spine as half carcasses. Of the operation

platforms, the second is mobile. The pedals system on the Platform is the

pneumatic switchboard that enables up and down movement. The operator on the

platform, operates the crosscut saw from the very top level all along the spine.

By operating the crosscut saw and with its cutting speed, the platform is moved

downwards. The system works with 2 pistons. Pistons provide the floor to move up

and down without vibration and without inclination. Thus the employee working at

carcass splitting performs his job without damaging the body.

TECHNICAL CHARACTERISTICS

Carcass division platforms are manufactured in general at the size of 140 x 160

mm with the smallest at the size of 800 x 1000mm, according to the structure of

the slaughterhouse. Railings with cork hit 5 mm thick plates are used on the

platform floor and railings are made of sheets 1mm meat thickness or plated with

hot submerged galvanize.

2 (two) pneumatic pistons mounted at the back of the platform are designed at

the capacity to lift it at the height of 1500 mm at fixed plane. At the back

railing part, there is the blade sterile pot and hand washing basin. On the

floor, it is mounted as available to be controlled at both directions with 2(two)

pedals.