FUNCTION

On the processing band, the trotters of the front and back feet are taken

initially. Then using the blade, the remaining parts of skin on the feet are

flayed. The skins opened at the ends of the feet are fixed on the machine chain

by their two feet. The drum is first stretched by rotating, then the flaying

process is started from top downwards.

While the drum moves downward, it wraps around itself the hide it has taken from

the body. The system working with a given tolerance is to avoid tearing of the

hide during flaying as well as to prevent the meat of the body to remain on the

hide with the angle of 90 degrees between the body and the machine.

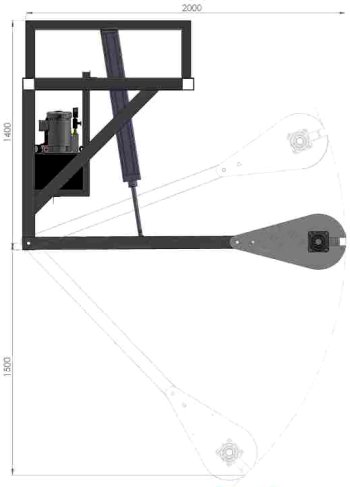

TECHNICAL CHARACTERISTICS

The full trunk is produced of inoxal (304) material. Chain winding drum is

designed as convex and operates with hydro-engine power. The drum rotates at the

rate of 7-22 rpm and simultaneously the lifting arms working hydraulically move

from the summit down to the floor at the speed of 10 seconds/meter.

The drum winding the hide around itself, turns backwards at the same rate taking

the hide down to the floor to the hide shooting space. The components of ring

chain and joints used in this system are made of inox (304). Enabling movement

in four directions, the system is operated with fixed panel control rod.